We had a chat with Dr. Lars Hancke, Manager Business Development Flexible Packaging, hubergroup Print Solutions, about the PrintCYC project. What the project is about, what successes were already achieved and why hubergroup thinks so highly of such cooperations, you can find out in the following interview.

hubergroup is a member of the PrintCYC consortium. What is PrintCYC and how did this association come about?

PrintCYC was founded in 2019 by a group of companies along the flexible packaging value chain. In addition to hubergroup Print Solutions, current members are the machine manufacturers Brückner Maschinenbau, Kiefel and PackSys Global, Profol as a specialist for PP (polypropylene) films, the flexible packaging manufacturer Constantia Flexibles and the recycling technology specialist Erema.

The initiative is coordinated by Annett Kaeding-Koppers, independent consultant for packaging and sustainability projects.

The aim of PrintCYC is to optimise the design of printed PE (polyethylene) and PP packaging for mechanical recycling. The influence of the printing inks on the recycling process and on the quality of the recyclates obtained is a particular focus.

You are responsible on the part of hubergroup for the technical development within the framework of this project. How do you assess the project and the first results?

In the current design guidelines for assessing the recyclability of flexible packaging, reference is only made to the properties of the printing ink in a relatively general way. The influence of the ink composition on the recycling process is not reflected.

For us as ink manufacturers, but also for the other participants in the value chain, it is therefore important to understand and evaluate this influence more precisely.

What specific findings were you able to draw from this?

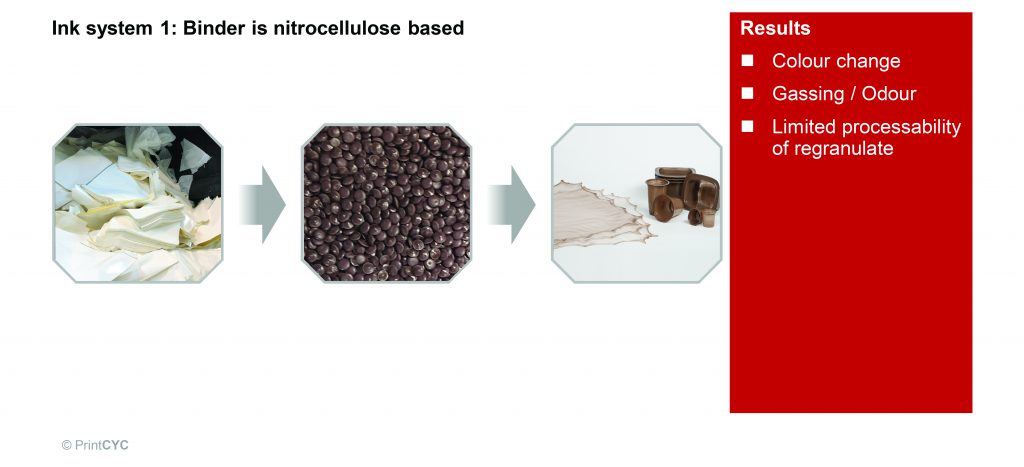

High temperatures in the order of 240 – 250°C occur during the recycling process. The thermal resistance of the printing inks is therefore of considerable importance. We were able to show that recycling is possible with the usual NC (nitrocellulose)-based packaging printing inks, but that the quality of the recyclates still has potential for improvement, especially with a higher recycled content.

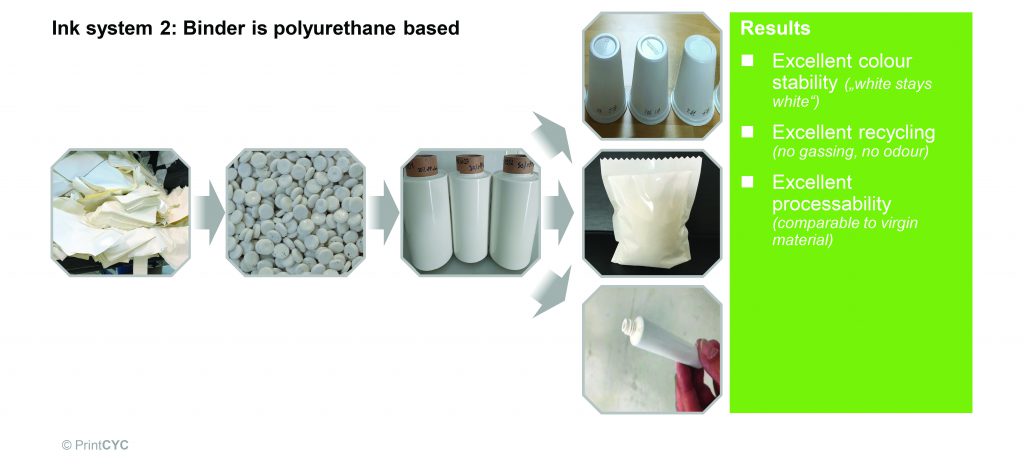

If, on the other hand, a more thermally stable binder is used, as in our polyurethane-based inks of the Gecko Platinum series, the recyclate quality improves considerably – in sensory, optical and mechanical terms.

We almost reach the level of virgin material here – with the right thermostable ink system, the recyclates are thus also suitable for higher-quality applications.

For me, the project is a successful example of how efficient cooperation can provide essential impulses for the development of sustainable packaging concepts.

The results from the PrintCYC project are a joint effort of the individual partner companies. What contribution has the hubergroup made here?

Printing ink and its influence on recycling are the focus of the project. We contribute our know-how here and help to select the most promising formulations and to evaluate the properties of the recyclate with regard to the ink ingredients. Here we have provided support, for example, by analysing the recyclates with regard to possible degradation products from the ink.

What are the next steps in the PrintCYC project?

We have made significant progress with the selection of the Gecko Platinum ink system.

We are currently in the final phase of defining the goals for the next phase of the project. We will examine the influences of the individual ink components in more detail. Another focus will be the more detailed analysis and evaluation of possible degradation products of the inks due to thermal stress in the recycling process.

hubergroup has always been involved in (research) projects and initiatives with partners or customers. What is special about such cooperations?

The aim of our research projects is to develop printing ink solutions for current market requirements and especially for those of tomorrow.

Here it is important to be in close contact with our customers, but also with other partners from the packaging industry, to recognise trends and to steer our development activities accordingly.

Direct cooperation with customers and partners allows us to better understand the properties of our colours in practical applications and in the context of the other components of the packaging, so that targeted optimisations are possible.

Especially in the area of sustainability, we are challenged as an entire industry to rethink and optimise traditional concepts. No one company can do this alone; it is only possible through appropriate collaborations such as PrintCYC.